In general, we don’t do them for a number of reasons.

Firstly, they are very labour intensive to produce. Each wire must be terminated manually, both in the connector that goes to the Adaptronic ECU and to the factory ECU connector. This makes them very expensive to produce. Even when we did make them for the old e420c ECU, we sold them at a loss and only because it helped to sell e420c ECUs.

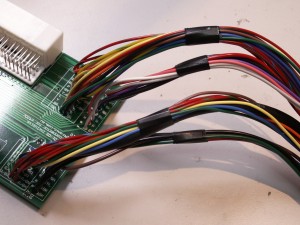

Secondly, they never look pretty enough for the amount that people want to pay for them. The factory ECU connectors are only available as a PCB mounting connector, not a wire-in-harness / free type connector. So when companies make them up, they are bending out the pins and soldering wires to the pins. This wasn’t what the connector was designed for and is very labour intensive. The alternative was the way we did it, which was to mount the connector to a circuit board, as it was intended. However this solution doesn’t look pretty unless it goes into an enclosure, which then has to be designed for the particular connector type and manufactured, and for the volume that needs to be done it’s just not cost effective.

Thirdly, and this is the main reason, the ECU doesn’t know what it’s connected to, which means that the operator has to look up a separate document to see how the aux outputs are mapped for example.

These challenges were actually the main reason for us developing the Select ECU platform, rather than just bringing out an update for the e420c. Now rather than manufacturing patch looms, we just do a specific ECU for the particular car. This looks pretty, is more robust, is cheaper to manufacture and the software can show the operator all the outputs.